Deep Drawing Press Process Structure

Deep drawing press is mainly suitable for the metal thin plate stretching type cylinder forming process. After the combination of the concave die, the punch and the bead ring, the circular cylinder can be stretched or the square cylinder can be stretched. Stretch stamping of commonly used auto parts, can also be used for household and kitchen appliances (gas range, auto parts drawn, and range hood shell stretching etc).

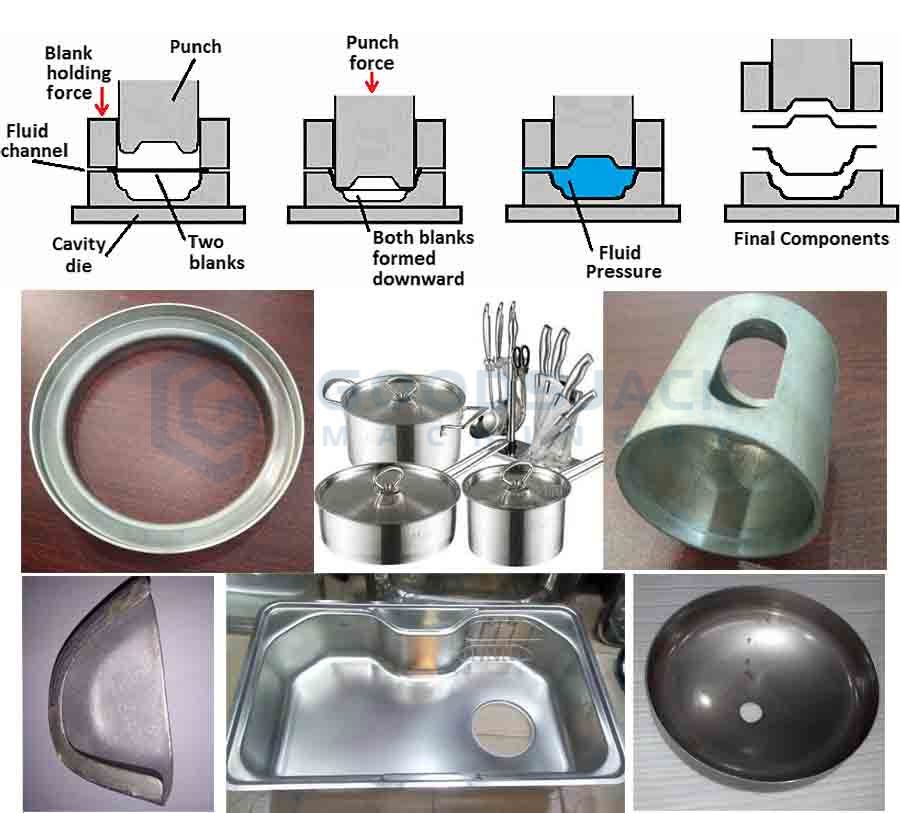

Double Action Deep Drawing Press Blank Hydroforming

The use of two blanks during a hybrid hydroforming operation is also possible. This allows for the press to essentially double its productivity, but can usually only be applied to two geometries which can be formed with the same pressure cycle and blank holding force (however [100] looked at using counter pressure on one blank to compensate). The operation shown would be a hybrid dual sheet hydroforming process and would work by first pressing both sheets and then pumping fluid in between them while the punch backs off.

评论

发表评论