How to Prevent Filter Clogging in Hydraulic Press Machine

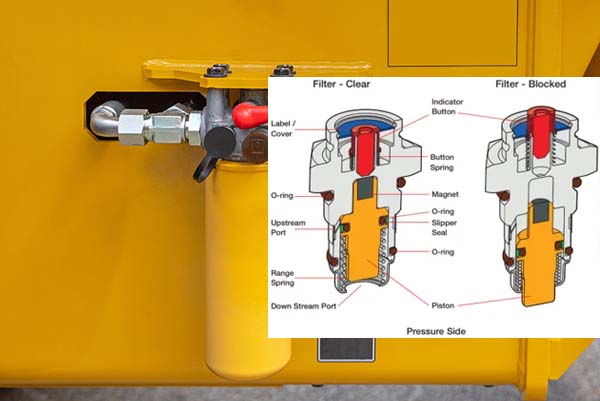

How to prevent filter clogging in hydraulic press machine. Generally, during the working process of the filter, the surface of the filter element will gradually heal, causing clogging. It is a normal phenomenon. The clogging mentioned here is a serious clogging that is known to cause malfunction of the hydraulic machine. After the filter is clogged, it will at least cause Poor pump oil and pump failure. Noise, the system cannot absorb enough oil but the pressure cannot rise. A large number of bubbles appear in the hydraulic oil and the filter element is clogged, which may cause breakdown failure due to increased pressure.

The filter function of the hydraulic press machine is to filter out impurities mixed in the hydraulic oil, reduce the pollution of the oil in the system, and ensure the normal operation of the hydraulic machine. The faults caused by the hydraulic machine filter are mainly manifested in poor filtration effect and failure to ensure that the oil is clean. The reasons for the damage and deformation of the filter element include: clogging of the filter element and incorrect selection. Troubleshooting method: Check and clean the oil filter promptly and regularly; correctly select a filter with pressure resistance, strength, and flow capacity that meets the requirements for the hydraulic press machine, and take corresponding countermeasures for various special reasons.

For metal mesh hydraulic filters, when the ambient temperature is high, the local oil temperature at the hydraulic filter is high, exceeding or close to the melting point of the welding point. In addition, the original welding is not strong, and the impact of the oil will cause desoldering. For example, the mesh filter at the inlet of the high-pressure plunger pump has been changed to silver solder many times, and their melting point has been greatly improved. Hydraulic press machines mostly refer to metal powder sintered filters. After falling particles enter the system, they block the throttle hole and jam the valve core. The reason is that the sintered powder filter element is of poor quality, so a qualified sintered oil filter must be selected.

Prevent Filter Clogging in Hydraulic Press Machine

The filter function of the hydraulic press machine is to filter out impurities mixed in the hydraulic oil, reduce the pollution of the oil in the system, and ensure the normal operation of the hydraulic machine. The faults caused by the hydraulic machine filter are mainly manifested in poor filtration effect and failure to ensure that the oil is clean. The reasons for the damage and deformation of the filter element include: clogging of the filter element and incorrect selection. Troubleshooting method: Check and clean the oil filter promptly and regularly; correctly select a filter with pressure resistance, strength, and flow capacity that meets the requirements for the hydraulic press machine, and take corresponding countermeasures for various special reasons.

For metal mesh hydraulic filters, when the ambient temperature is high, the local oil temperature at the hydraulic filter is high, exceeding or close to the melting point of the welding point. In addition, the original welding is not strong, and the impact of the oil will cause desoldering. For example, the mesh filter at the inlet of the high-pressure plunger pump has been changed to silver solder many times, and their melting point has been greatly improved. Hydraulic press machines mostly refer to metal powder sintered filters. After falling particles enter the system, they block the throttle hole and jam the valve core. The reason is that the sintered powder filter element is of poor quality, so a qualified sintered oil filter must be selected.

评论

发表评论