Design & Optimization of 4 Post Hydraulic Press

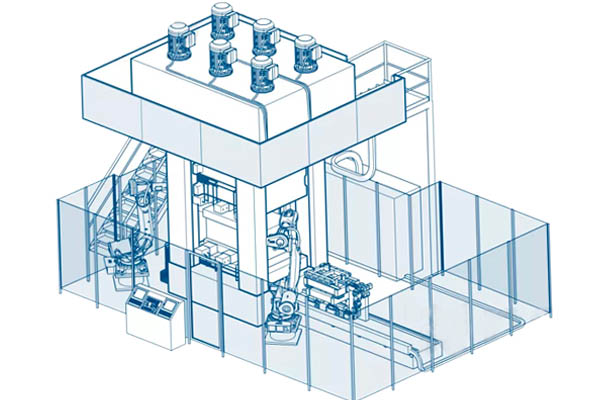

Do you know 4 post hydraulic press works? 4 post hydraulic press is a kind of equipment that uses the static pressure of hydraulic oil to be transported by oil pump to process metal, plastic, rubber, wood, powder and other products. 4 post hydraulic presses are used in the heavy industry mainly in automatic processes of pressing, bending, cutting and hot forging. Most of them operate in robotic cells with automatic handling systems using modern manipulators and conveyors.

The optimal design scheme of the 4 post hydraulic press can be adjusted and improved according to the actual situation.

Design & Optimization of 4 Post Hydraulic Press

1. Needs analysis and current situation assessment

In-depth communication with users to understand the actual use requirements, working environment, processing technology and other requirements of the four-column hydraulic press, and determine the specific goals and indicators of optimized design.

Carry out comprehensive performance testing and structural evaluation of the existing four-column hydraulic press, including pressure test, speed test, accuracy test, structural strength analysis, etc., collect relevant data, and find out the existing problems and deficiencies.

2. Optimize the formulation of design schemes

According to the results of demand analysis and current situation assessment, the design team is organized to formulate a detailed optimization design plan, including specific optimization measures and design parameters for hydraulic system, structure, control system, etc.

Computer-aided design (CAD) and simulation analysis software are used to carry out virtual modeling and performance simulation analysis of the optimized design scheme, verify the feasibility and effectiveness of the scheme, and further optimize and adjust the scheme according to the simulation results.

3. Design and manufacture of parts

According to the optimized design scheme, the detailed design of each part of the four-column hydraulic press is carried out, the two-dimensional engineering drawings are drawn, and the processing process specification is compiled.

Select high-quality raw materials and parts suppliers, and manufacture and process parts in strict accordance with design requirements and process regulations to ensure the quality and accuracy of parts.

4. Equipment assembly and commissioning The manufactured parts are transported to the assembly site, and the assembly of the four-column hydraulic press is carried out according to the assembly drawings to ensure that the parts are installed correctly and connected firmly.

After the assembly is completed, a comprehensive debugging of the equipment is carried out, including hydraulic system debugging, electrical control system debugging, mechanical motion debugging, etc., checking whether the performance indicators of the equipment meet the design requirements, and rectifying and optimizing the problems found in time. 5. Performance testing and acceptance

After the equipment is debugged, strict performance tests are carried out, including pressure test, speed test, accuracy test, energy consumption test, etc., the test data is recorded, and the optimization design target is compared and analyzed.

Organize users and relevant experts to accept the 4 post hydraulic press, and conduct a comprehensive evaluation of the performance, quality, reliability and other aspects of the equipment according to the acceptance standards and test results. If there is a problem, the rectification and optimization will continue until the acceptance is passed.

Through the optimized design scheme of the above 4 post hydraulic press, the performance, energy efficiency, structural reliability and operation convenience of the equipment can be significantly improved, and better economic benefits and market competitiveness can be brought to the enterprise. In the implementation process, it is necessary to fully consider the technical requirements and quality control of design, manufacturing, commissioning and other links to ensure the smooth realization of the optimized design goals.

Delishi Machinery Technology CO.,LTD.

Add: No.3 JinFu Road, Jinma Industrial Park, LiaoBu town, DongGuan City, GuanDong Province, China.

E-mail: Mr. Lee info@goodsjack.com, info@dgdelishi.com;

Web: www.goodsjack.com/ www.dgdelishi.com www.hydraulic-press-machine.com

Tel: +86-769-83061993 / +86-13509801050

Contact: Ms. Eva Lee

E-mail: sales@goodsjack.com

The optimal design scheme of the 4 post hydraulic press can be adjusted and improved according to the actual situation.

Design & Optimization of 4 Post Hydraulic Press

1. Needs analysis and current situation assessment

In-depth communication with users to understand the actual use requirements, working environment, processing technology and other requirements of the four-column hydraulic press, and determine the specific goals and indicators of optimized design.

Carry out comprehensive performance testing and structural evaluation of the existing four-column hydraulic press, including pressure test, speed test, accuracy test, structural strength analysis, etc., collect relevant data, and find out the existing problems and deficiencies.

2. Optimize the formulation of design schemes

According to the results of demand analysis and current situation assessment, the design team is organized to formulate a detailed optimization design plan, including specific optimization measures and design parameters for hydraulic system, structure, control system, etc.

Computer-aided design (CAD) and simulation analysis software are used to carry out virtual modeling and performance simulation analysis of the optimized design scheme, verify the feasibility and effectiveness of the scheme, and further optimize and adjust the scheme according to the simulation results.

3. Design and manufacture of parts

According to the optimized design scheme, the detailed design of each part of the four-column hydraulic press is carried out, the two-dimensional engineering drawings are drawn, and the processing process specification is compiled.

Select high-quality raw materials and parts suppliers, and manufacture and process parts in strict accordance with design requirements and process regulations to ensure the quality and accuracy of parts.

4. Equipment assembly and commissioning The manufactured parts are transported to the assembly site, and the assembly of the four-column hydraulic press is carried out according to the assembly drawings to ensure that the parts are installed correctly and connected firmly.

After the assembly is completed, a comprehensive debugging of the equipment is carried out, including hydraulic system debugging, electrical control system debugging, mechanical motion debugging, etc., checking whether the performance indicators of the equipment meet the design requirements, and rectifying and optimizing the problems found in time. 5. Performance testing and acceptance

After the equipment is debugged, strict performance tests are carried out, including pressure test, speed test, accuracy test, energy consumption test, etc., the test data is recorded, and the optimization design target is compared and analyzed.

Organize users and relevant experts to accept the 4 post hydraulic press, and conduct a comprehensive evaluation of the performance, quality, reliability and other aspects of the equipment according to the acceptance standards and test results. If there is a problem, the rectification and optimization will continue until the acceptance is passed.

Through the optimized design scheme of the above 4 post hydraulic press, the performance, energy efficiency, structural reliability and operation convenience of the equipment can be significantly improved, and better economic benefits and market competitiveness can be brought to the enterprise. In the implementation process, it is necessary to fully consider the technical requirements and quality control of design, manufacturing, commissioning and other links to ensure the smooth realization of the optimized design goals.

Delishi Machinery Technology CO.,LTD.

Add: No.3 JinFu Road, Jinma Industrial Park, LiaoBu town, DongGuan City, GuanDong Province, China.

E-mail: Mr. Lee info@goodsjack.com, info@dgdelishi.com;

Web: www.goodsjack.com/ www.dgdelishi.com www.hydraulic-press-machine.com

Tel: +86-769-83061993 / +86-13509801050

Contact: Ms. Eva Lee

E-mail: sales@goodsjack.com

评论

发表评论