How Hydraulic Press Machines Are Used for Precision Stamping & Forging

Hydraulic press machines have become indispensable in precision stamping and forging, thanks to their ability to deliver controlled force, consistent pressure, and micron-level accuracy. These capabilities make them ideal for shaping metals into complex, high-quality parts—whether for automotive components, aerospace parts, or industrial hardware.

Following we'll explores how hydraulic press machines are used in stamping and forging, their advantages over mechanical presses, and key applications across industries.

Precision Stamping with Hydraulic Presses

Stamping involves cutting, bending, and shaping sheet metal into desired forms. Hydraulic presses provide the consistent pressure and precision needed for complex designs.

Key Stamping Applications:

✔ Automotive Parts – Body panels, brackets, and engine components.

✔ Electronics – Metal casings, connectors, and heat sinks.

✔ Appliances – Refrigerator panels, washing machine drums.

✔ Aerospace – Lightweight aircraft components.

Advantages of Hydraulic Presses in Stamping:

Deep Drawing Capability – Smoothly forms deep, intricate shapes without tearing.

Reduced Material Waste – Precise force application minimizes errors.

Flexible Tooling – Easily adjustable for different part designs.

Precision Forging with Hydraulic Presses

Forging involves shaping metal under extreme pressure to enhance strength and durability. Hydraulic presses are ideal for closed-die forging, where precision is critical.

Key Forging Applications:

✔ Automotive – Crankshafts, gears, and suspension parts.

✔ Aerospace – Turbine blades, landing gear components.

✔ Oil & Gas – High-strength valves and flanges.

✔ Tool & Die – Durable molds and industrial tools.

Advantages of Hydraulic Presses in Forging: Uniform Pressure Distribution – Eliminates weak spots in forged parts.

Slow, Controlled Deformation – Prevents cracking in high-strength alloys.

High Tonnage Capability – Can handle 500T to 10,000T+ for heavy forging.

How Hydraulic Presses Improve Precision in Stamping & Forging

1. Programmable Controls & Automation

PLC systems allow precise force and speed adjustments.

Automated feeding & ejection reduces human error.

2. Consistent Force Application

Unlike mechanical presses, hydraulic presses maintain constant pressure throughout the stroke.

3. Adaptability for Complex Geometries

Ideal for asymmetrical and deep-drawn parts.

4. Reduced Defects & Higher Quality

Minimizes cracks, warping, and uneven thickness.

Conclusion

Hydraulic press machines are indispensable for precision stamping and forging, offering superior control, flexibility, and durability compared to mechanical alternatives. Whether producing automotive parts, aerospace components, or industrial tools, hydraulic presses ensure high-quality, defect-free results.

Need a hydraulic press for your stamping or forging needs? Contact Goodsjack Hydraulic Machinery for expert solutions tailored to your industry!

From the (SZX)Shenzhen Bao'an International Airport and (CAN)Guangzhou Baiyun International Airport to our factory 1.5 hour's driving. Warmly welcome to visit us at any time.

Delishi Machinery Technology Co.,Ltd.

Goodsjack Hydraulic Machinery Co.,Ltd.

Tel: +86-769-88057683 83223615

Fax: +86-769-83231691

Address: No3 Jinfu Road, Jinma Industrial Park, Liaobu, Dongguan City, GuanDong Province, China

E-mail: info@goodsjack.com, sales@goodsjack.com, info@dgdelishi.com

WhatsApp/Wechat: +86-13642957273 Alice

WhatsApp/Wechat: +86-13509801050 Eva

Web: https://www.hydraulic-press-machine.com https://www.kccnc.com

Web: https://www.goodsjack.com

Following we'll explores how hydraulic press machines are used in stamping and forging, their advantages over mechanical presses, and key applications across industries.

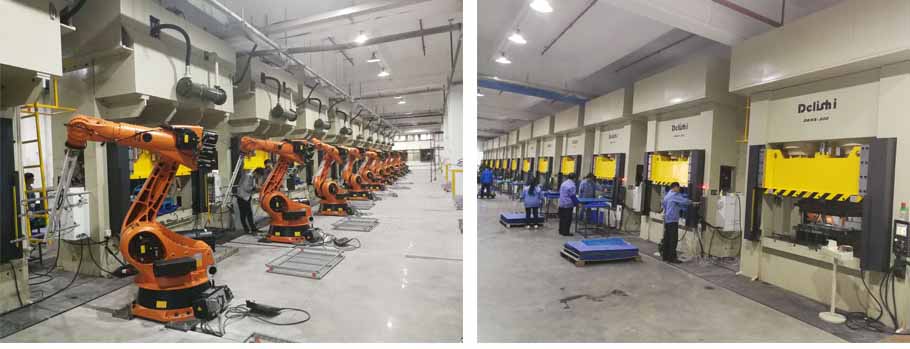

Goodsjack Hydraulic Press Machines

Precision Stamping with Hydraulic Presses

Stamping involves cutting, bending, and shaping sheet metal into desired forms. Hydraulic presses provide the consistent pressure and precision needed for complex designs.

Key Stamping Applications:

✔ Automotive Parts – Body panels, brackets, and engine components.

✔ Electronics – Metal casings, connectors, and heat sinks.

✔ Appliances – Refrigerator panels, washing machine drums.

✔ Aerospace – Lightweight aircraft components.

Advantages of Hydraulic Presses in Stamping:

Deep Drawing Capability – Smoothly forms deep, intricate shapes without tearing.

Reduced Material Waste – Precise force application minimizes errors.

Flexible Tooling – Easily adjustable for different part designs.

Precision Forging with Hydraulic Presses

Forging involves shaping metal under extreme pressure to enhance strength and durability. Hydraulic presses are ideal for closed-die forging, where precision is critical.

Key Forging Applications:

✔ Automotive – Crankshafts, gears, and suspension parts.

✔ Aerospace – Turbine blades, landing gear components.

✔ Oil & Gas – High-strength valves and flanges.

✔ Tool & Die – Durable molds and industrial tools.

Advantages of Hydraulic Presses in Forging: Uniform Pressure Distribution – Eliminates weak spots in forged parts.

Slow, Controlled Deformation – Prevents cracking in high-strength alloys.

High Tonnage Capability – Can handle 500T to 10,000T+ for heavy forging.

How Hydraulic Presses Improve Precision in Stamping & Forging

1. Programmable Controls & Automation

PLC systems allow precise force and speed adjustments.

Automated feeding & ejection reduces human error.

2. Consistent Force Application

Unlike mechanical presses, hydraulic presses maintain constant pressure throughout the stroke.

3. Adaptability for Complex Geometries

Ideal for asymmetrical and deep-drawn parts.

4. Reduced Defects & Higher Quality

Minimizes cracks, warping, and uneven thickness.

Conclusion

Hydraulic press machines are indispensable for precision stamping and forging, offering superior control, flexibility, and durability compared to mechanical alternatives. Whether producing automotive parts, aerospace components, or industrial tools, hydraulic presses ensure high-quality, defect-free results.

Need a hydraulic press for your stamping or forging needs? Contact Goodsjack Hydraulic Machinery for expert solutions tailored to your industry!

From the (SZX)Shenzhen Bao'an International Airport and (CAN)Guangzhou Baiyun International Airport to our factory 1.5 hour's driving. Warmly welcome to visit us at any time.

Delishi Machinery Technology Co.,Ltd.

Goodsjack Hydraulic Machinery Co.,Ltd.

Tel: +86-769-88057683 83223615

Fax: +86-769-83231691

Address: No3 Jinfu Road, Jinma Industrial Park, Liaobu, Dongguan City, GuanDong Province, China

E-mail: info@goodsjack.com, sales@goodsjack.com, info@dgdelishi.com

WhatsApp/Wechat: +86-13642957273 Alice

WhatsApp/Wechat: +86-13509801050 Eva

Web: https://www.hydraulic-press-machine.com https://www.kccnc.com

Web: https://www.goodsjack.com

评论

发表评论