Hydraulic System Of Hydraulic Press Machine

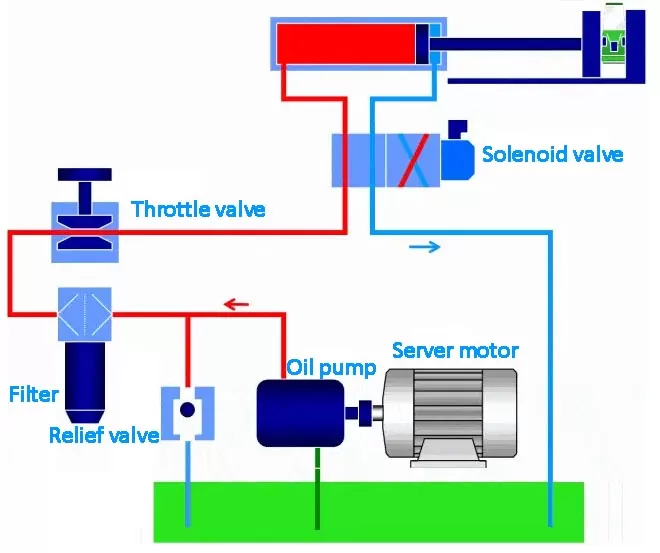

A hydraulic press machine is a mechanical device that shapes, extrudes, or stretches a workpiece by applying force. The role of the hydraulic system on the press is to provide power and control the mechanical movement.

hydraulic system of hydraulic press machine

Hydraulic Pump: The hydraulic pump is the power source of the hydraulic system, which is responsible for pumping the hydraulic oil out of the tank and increasing its pressure to the required working pressure. Hydraulic pumps are usually piston or gear type construction, which is characterized by high pressure and high flow rate.

Oil tank: The oil tank is the oil reservoir of the hydraulic system, which holds the hydraulic oil and removes impurities through the filter. The oil tank also has the function of cooling the hydraulic oil to ensure the stable operation of the system.

Hydraulic cylinder: The hydraulic cylinder is the actuator of the hydraulic system, which converts the hydraulic energy into mechanical energy and pushes the press to work. Hydraulic cylinders are usually composed of pistons, piston rods and cylinder blocks, and by controlling the inflow and outflow of hydraulic oil, the telescopic movement of the cylinder block is realized.

Valves: Valves in hydraulic systems are used to control the flow direction, flow, and pressure of hydraulic fluid. Common hydraulic valves include check valves, relief valves, proportional valves, etc. These valves can be combined and controlled as needed to achieve precise control of the hydraulic system.

Pipelines: The pipelines of the hydraulic system are used to transport hydraulic oil and transfer hydraulic energy from the hydraulic pump to the hydraulic cylinder. The pipeline is usually composed of high-pressure and pressure-resistant steel pipes or high-pressure hoses to ensure the safe delivery of hydraulic oil.

Hydraulic oil: The hydraulic system uses special hydraulic oil as the working medium. Hydraulic fluids have good lubricity, tightness and thermal stability to maintain fluidity at high pressures. At the same time, the hydraulic oil also needs to have anti-oxidation, anti-corrosion and anti-foaming properties to ensure the long-term stable operation of the system.

The use of hydraulic systems on hydraulic press machines provides high pressure, high precision and high stability of power for a wide range of forming, compression and drawing processes. The advantage of the hydraulic system is that it can provide a large force output, and it is characterized by high reliability, fast response and high precision. At the same time, the hydraulic system can also be automatically controlled, improving production efficiency and work safety. In short, the application of hydraulic system in the hydraulic press machine enables the press to complete various process operations more efficiently, accurately and reliably.

GOODSJACK HYDRAULIC MACHINERY CO., LTD

DELISHI MACHINERY TECHNOLOGY CO., LTD

Hydraulic Press Machine, Hydraulic Forging Press Manufacturer

Web: www.hydraulic-press-machine.com

www.goodsjack.com

Tel: +86-769-83061993 83223615

Fax: +86-769-83231691

Dongguan Factory

General Factory : No3, Jinfu Road, Jinma Industrial Park, Liaobu Town, Dongguan, Guangdong, China

Branch Factory: No210 Heshi Road, Qiaotou Town, Dongguan, Guangdong, China

Hubei Factory

Address: Sanhua Industrial Park, Binjiang New Area, Huangshi, Hubei, China

Eva Lee Sales Manager

Email: sales@goodsjack.com

WhatsApp/Wechat:+ 86 13509801050

Alice Xu Sales Manager

Skype: alice.goodsjack

Email: sales1@goodsjack.com

WhatsApp/Wechat: +86 13642957273

Hydraulic Pump: The hydraulic pump is the power source of the hydraulic system, which is responsible for pumping the hydraulic oil out of the tank and increasing its pressure to the required working pressure. Hydraulic pumps are usually piston or gear type construction, which is characterized by high pressure and high flow rate.

Oil tank: The oil tank is the oil reservoir of the hydraulic system, which holds the hydraulic oil and removes impurities through the filter. The oil tank also has the function of cooling the hydraulic oil to ensure the stable operation of the system.

Hydraulic cylinder: The hydraulic cylinder is the actuator of the hydraulic system, which converts the hydraulic energy into mechanical energy and pushes the press to work. Hydraulic cylinders are usually composed of pistons, piston rods and cylinder blocks, and by controlling the inflow and outflow of hydraulic oil, the telescopic movement of the cylinder block is realized.

Valves: Valves in hydraulic systems are used to control the flow direction, flow, and pressure of hydraulic fluid. Common hydraulic valves include check valves, relief valves, proportional valves, etc. These valves can be combined and controlled as needed to achieve precise control of the hydraulic system.

Pipelines: The pipelines of the hydraulic system are used to transport hydraulic oil and transfer hydraulic energy from the hydraulic pump to the hydraulic cylinder. The pipeline is usually composed of high-pressure and pressure-resistant steel pipes or high-pressure hoses to ensure the safe delivery of hydraulic oil.

Hydraulic oil: The hydraulic system uses special hydraulic oil as the working medium. Hydraulic fluids have good lubricity, tightness and thermal stability to maintain fluidity at high pressures. At the same time, the hydraulic oil also needs to have anti-oxidation, anti-corrosion and anti-foaming properties to ensure the long-term stable operation of the system.

The use of hydraulic systems on hydraulic press machines provides high pressure, high precision and high stability of power for a wide range of forming, compression and drawing processes. The advantage of the hydraulic system is that it can provide a large force output, and it is characterized by high reliability, fast response and high precision. At the same time, the hydraulic system can also be automatically controlled, improving production efficiency and work safety. In short, the application of hydraulic system in the hydraulic press machine enables the press to complete various process operations more efficiently, accurately and reliably.

GOODSJACK HYDRAULIC MACHINERY CO., LTD

DELISHI MACHINERY TECHNOLOGY CO., LTD

Hydraulic Press Machine, Hydraulic Forging Press Manufacturer

Web: www.hydraulic-press-machine.com

www.goodsjack.com

Tel: +86-769-83061993 83223615

Fax: +86-769-83231691

Dongguan Factory

General Factory : No3, Jinfu Road, Jinma Industrial Park, Liaobu Town, Dongguan, Guangdong, China

Branch Factory: No210 Heshi Road, Qiaotou Town, Dongguan, Guangdong, China

Hubei Factory

Address: Sanhua Industrial Park, Binjiang New Area, Huangshi, Hubei, China

Eva Lee Sales Manager

Email: sales@goodsjack.com

WhatsApp/Wechat:+ 86 13509801050

Alice Xu Sales Manager

Skype: alice.goodsjack

Email: sales1@goodsjack.com

WhatsApp/Wechat: +86 13642957273

评论

发表评论