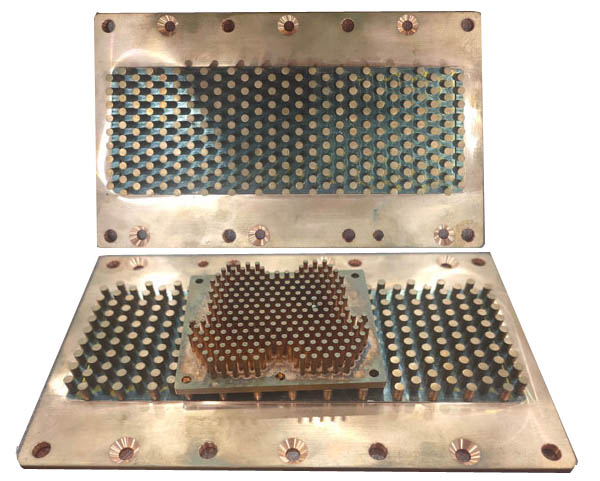

IGBT Heat Sink Cold Forging Extrusion Press

The IGBT heat sink cold forging extrusion press is a specialized machine used in the manufacturing process of IGBT (Insulated Gate Bipolar Transistor) heat sinks. IGBT Heat Sink Cold Forging Extrusion Press of Delishi/Goodsjack Hydraulic Machinery, is specially designed and made for forming in one punch.Cold forging is a metal forming process that involves shaping metal at room temperature using compressive forces.

Features of Delishi/Goodsjack IGBT Heat Sink Cold Forging Extrusion Press

The use of a servo control system guarantee us to save 50-70% energy compared to a standard press.

Pressure stability,pressure error ±1bar,repeatable positioning accuracy up to±0.02mm.

Low failure rate,automatic alarm and fault indication,one-button reset function.

Remote maintenance service can be realized.

Can set up multi-stage pressure, multi-speed and contiouns fixed-pressure function.

Adopting an integral frame structure, high strength, low distortion and durability.

As the leading manufacturer of IGBT Heat Sink Cold Forging Extrusion Press, Delishi/Goodsjack obtained trust from clients for supplying and manufacturing reliable heatsink products. We stocked hundreds of numerous cold forging heat sink to fully support your business.

Delishi Machinery Technology CO.,LTD.

Add: No.3 JinFu Road, Jinma Industrial Park, LiaoBu town, DongGuan City, GuanDong Province, China.

E-mail: Mr. Lee info@goodsjack.com, info@dgdelishi.com;

Web: www.goodsjack.com/ www.dgdelishi.com www.hydraulic-machine.com

Tel: +86-769-83061993 / +86-13509801050

Contact: Ms. Eva Lee

E-mail: sales@goodsjack.com

Contact: Ms. Alice Xu

E-mail: sales1@goodsjack.com

IGBT Heat Sink Cold Forging Extrusion Press

Features of Delishi/Goodsjack IGBT Heat Sink Cold Forging Extrusion Press

The use of a servo control system guarantee us to save 50-70% energy compared to a standard press.

Pressure stability,pressure error ±1bar,repeatable positioning accuracy up to±0.02mm.

Low failure rate,automatic alarm and fault indication,one-button reset function.

Remote maintenance service can be realized.

Can set up multi-stage pressure, multi-speed and contiouns fixed-pressure function.

Adopting an integral frame structure, high strength, low distortion and durability.

cold forging extrusion press

As the leading manufacturer of IGBT Heat Sink Cold Forging Extrusion Press, Delishi/Goodsjack obtained trust from clients for supplying and manufacturing reliable heatsink products. We stocked hundreds of numerous cold forging heat sink to fully support your business.

Delishi Machinery Technology CO.,LTD.

Add: No.3 JinFu Road, Jinma Industrial Park, LiaoBu town, DongGuan City, GuanDong Province, China.

E-mail: Mr. Lee info@goodsjack.com, info@dgdelishi.com;

Web: www.goodsjack.com/ www.dgdelishi.com www.hydraulic-machine.com

Tel: +86-769-83061993 / +86-13509801050

Contact: Ms. Eva Lee

E-mail: sales@goodsjack.com

Contact: Ms. Alice Xu

E-mail: sales1@goodsjack.com

评论

发表评论