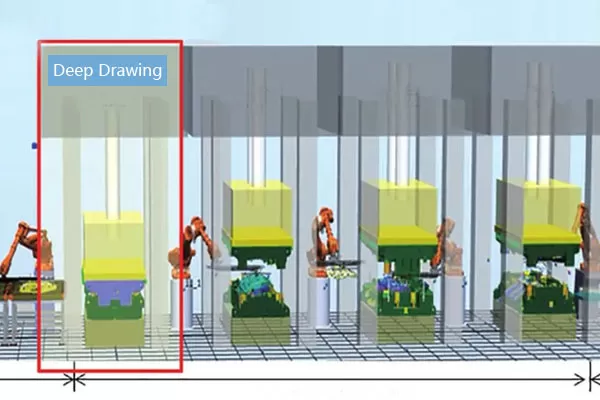

Deep Drawing Hydraulic Press Production Line Solution

A deep drawing hydraulic press production line is an integrated system designed for manufacturing complex metal parts through the deep drawing process, which involves forming sheet metal into three-dimensional shapes using hydraulic pressure. With the development of the manufacturing industry, enterprises have put forward higher requirements for the efficiency, stability and intelligence of the deep drawing hydraulic press production line. Goodsjack's deep drawing hydraulic press production line solution aims to build an advanced and reliable deep drawing hydraulic press production line for enterprises, helping them to improve production efficiency, reduce costs and improve product quality.

Deep Drawing Hydraulic Press Production Line Solution

Key Components

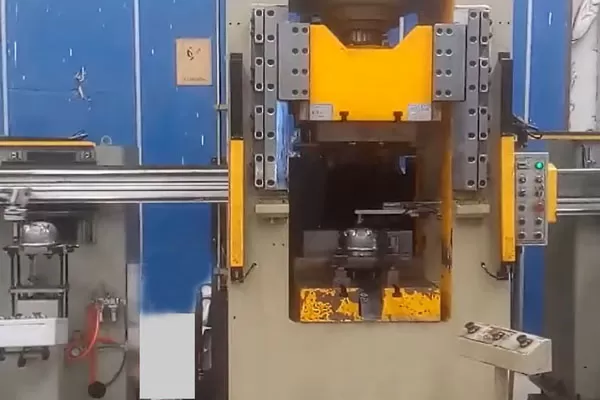

1. Hydraulic Press

● High-tonnage capacity (typically 100-5000 tons)

● Programmable hydraulic system with precise pressure control

● CNC controls for repeatable operations

2. Material Handling System

● Automated sheet feeding mechanism

● Blank preparation station (cutting to size)

● Transfer systems between operations

3. Tooling System

● Custom-designed dies and punches

● Quick-change tooling systems for flexible production

● Die cushion systems for wrinkle prevention

4. Ancillary Equipment

● Lubrication systems

● Part ejection mechanisms

● Scrap removal systems

Production Process Flow

1. Blank Preparation

● Coil unwinding and straightening

● Blank cutting to required dimensions

2. Drawing Operation

● First draw (main forming operation)

● Subsequent redrawing operations (if needed)

3. Secondary Operations

● Trimming and piercing

● Flanging and hemming

● Bottom finishing

4. Quality Control

● Dimensional inspection

● Surface quality checks

Deep Drawing Hydraulic Press Production Line Solution

Advantages

High Production Capacity: Capable of producing hundreds to thousands of parts per hour

Precision Forming: Consistent part quality with tight tolerances

Material Efficiency: Minimal scrap generation compared to other forming methods

Versatility: Can handle various materials (steel, aluminum, copper alloys) and thicknesses

Applications

Automotive components (fuel tanks, body panels)

Kitchenware (sinks, pots, pans)

Industrial containers and housings

Aerospace components

Customization Options

Automation Level: From semi-automatic to fully robotic lines

Press Configuration: Single-action, double-action, or triple-action presses

Control Systems: Basic to advanced CNC with IoT connectivity

Safety Systems: Light curtains, interlocks, and pressure monitoring

If you need deep drawing hydraulic press production line, please contact us, best hydraulic press solution will be provided for you.

GOODSJACK HYDRAULIC MACHINERY CO., LTD

DELISHI MACHINERY TECHNOLOGY CO., LTD

Hydraulic Press Machine, Hydraulic Forging Press Manufacturer

Web: www.hydraulic-press-machine.com

www.goodsjack.com

Tel: +86-769-83061993 83223615

Fax: +86-769-83231691

Dongguan Factory

General Factory : No3, Jinfu Road, Jinma Industrial Park, Liaobu Town, Dongguan, Guangdong, China

Branch Factory: No210 Heshi Road, Qiaotou Town, Dongguan, Guangdong, China

Hubei Factory

Address: Sanhua Industrial Park, Binjiang New Area, Huangshi, Hubei, China

Eva Lee Sales Manager

Email: sales@goodsjack.com

WhatsApp/Wechat:+ 86 13509801050

Alice Xu Sales Manager

Skype: alice.goodsjack

Email: sales1@goodsjack.com

WhatsApp/Wechat: +86 13642957273

Deep Drawing Hydraulic Press Production Line Solution

Key Components

1. Hydraulic Press

● High-tonnage capacity (typically 100-5000 tons)

● Programmable hydraulic system with precise pressure control

● CNC controls for repeatable operations

2. Material Handling System

● Automated sheet feeding mechanism

● Blank preparation station (cutting to size)

● Transfer systems between operations

3. Tooling System

● Custom-designed dies and punches

● Quick-change tooling systems for flexible production

● Die cushion systems for wrinkle prevention

4. Ancillary Equipment

● Lubrication systems

● Part ejection mechanisms

● Scrap removal systems

Production Process Flow

1. Blank Preparation

● Coil unwinding and straightening

● Blank cutting to required dimensions

2. Drawing Operation

● First draw (main forming operation)

● Subsequent redrawing operations (if needed)

3. Secondary Operations

● Trimming and piercing

● Flanging and hemming

● Bottom finishing

4. Quality Control

● Dimensional inspection

● Surface quality checks

Deep Drawing Hydraulic Press Production Line Solution

Advantages

High Production Capacity: Capable of producing hundreds to thousands of parts per hour

Precision Forming: Consistent part quality with tight tolerances

Material Efficiency: Minimal scrap generation compared to other forming methods

Versatility: Can handle various materials (steel, aluminum, copper alloys) and thicknesses

Applications

Automotive components (fuel tanks, body panels)

Kitchenware (sinks, pots, pans)

Industrial containers and housings

Aerospace components

Customization Options

Automation Level: From semi-automatic to fully robotic lines

Press Configuration: Single-action, double-action, or triple-action presses

Control Systems: Basic to advanced CNC with IoT connectivity

Safety Systems: Light curtains, interlocks, and pressure monitoring

If you need deep drawing hydraulic press production line, please contact us, best hydraulic press solution will be provided for you.

GOODSJACK HYDRAULIC MACHINERY CO., LTD

DELISHI MACHINERY TECHNOLOGY CO., LTD

Hydraulic Press Machine, Hydraulic Forging Press Manufacturer

Web: www.hydraulic-press-machine.com

www.goodsjack.com

Tel: +86-769-83061993 83223615

Fax: +86-769-83231691

Dongguan Factory

General Factory : No3, Jinfu Road, Jinma Industrial Park, Liaobu Town, Dongguan, Guangdong, China

Branch Factory: No210 Heshi Road, Qiaotou Town, Dongguan, Guangdong, China

Hubei Factory

Address: Sanhua Industrial Park, Binjiang New Area, Huangshi, Hubei, China

Eva Lee Sales Manager

Email: sales@goodsjack.com

WhatsApp/Wechat:+ 86 13509801050

Alice Xu Sales Manager

Skype: alice.goodsjack

Email: sales1@goodsjack.com

WhatsApp/Wechat: +86 13642957273

评论

发表评论